|

Dongguan Ming Rui Ceramic Technology Co.,ltd

|

Gold Index: 16085

High Precision Wearable Ceramic Gauge Block Sets Series Of 516 - 8 Pieces

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

<div style="background:url("/sc-productposting/node_modules/@alife/scc-maya-core/assets/images/blank.c15b249e.png") 0px -1px repeat-x rgb(

High Precision Wearable Ceramic Gauge Blocks sets series of 516 - 8 pieces

* Tests under room temperature environment;

* The above information is offered for comparison only. Exact

properties will vary depending on the manufacturing method

Machining

Machining tolerances are surprisingly tight, up to10 microns (.0005”).It can bemachined to a surfacefinishof less than 0.5 micron (20 microinch) and polished to a smoothness of 125 angstroms 0.5 microinch) average roughness. Most conventionalmachining processes can be used. Configurationsare limited only by available equipment and theexperience of the machinist.

>>> Typical Applications

- Precision coil formers, high voltage insulators

- Laser industry

- Spacers/reectors/cavities in laser assemblies

- High vacuum industry

- Thermal breaks

- Coil supports

- Vacuum feedthroughs

- Aerospace/space industry

Features of ceramic gauge blocks

1.Highly accurate, very low deviation from flatness, surface finish & nominal length

2.High resistance to wear & dimensionally stable

3.Superior wringing quality

Ceramic gauge blocks are extremely resistant to wear and scratches. As a result, any minor damage to the wringability of their measuring face is unlikely. Corrosion resistant, these gage blocks are resistant to sweaty hands, and normal wear and tear.

Company Introduction

Mingrui ceramic manufacture and provides zirconia & alumina ceramic components for a wide range of application like Mechanical Equipment, Electronic & Electrical, Oil Drilling, Medical, Chemical Industry etc. According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.

Precision Ceramics has years of experience designing and developing technical ceramic solutions for a wide variety of applications and industries.Ceramic accessories for wire and textile production. We offer this expertise to all of our customers to ensure the best design and materials are chosen for their specific application and needs. Ceramic accessories for wire and textile production,Typically, our custom technical ceramic components and parts we supply are used for one of three main reasons:

Precision Industrial Ceramic parts in machine parts

High temperature ceramics – crucibles, nozzles, lasers, furnace/kiln fixtures

Precision Industrial Ceramic parts in machine parts

Wear and corrosion resistant ceramics – plates, housings, gages, caps/lids

Precision Industrial Ceramic parts in machine parts

Electrical insulation ceramics – contact blocks, standoffs, fasteners, spacers

CPrecision Industrial Ceramic parts in machine parts

Precision Ceramics is one of the world’s premiere technical ceramic suppliers – contact us to see what technical ceramics we can create for you.

Precision Industrial Ceramic parts in machine parts

|

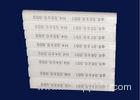

General Characteristics of Materials:

|

||||

|

Characteristic

|

Ceramics

|

Metals

|

Polymers

|

Refractory

|

|

Density

|

Low to High

|

Low to High

|

Low

|

Low to Medium

|

|

Hardness

|

High

|

Medium

|

low

|

Medium

|

|

Toughness

|

low

|

High

|

Medium

|

low

|

|

Wear Resistance

|

High

|

Medium

|

low

|

Medium

|

|

Tensile Strength

|

Low to Medium

|

High

|

low

|

low

|

|

Compressive Strength

|

High

|

Medium to High

|

low to Medium

|

High

|

|

Young’s Modulus

|

Medium to High

|

Low to High

|

Low

|

Medium

|

|

Dimensional Stability

|

High

|

low to Medium

|

low

|

/

|

|

Thermal Expansion

|

Low to Medium

|

Medium to High

|

High

|

low

|

|

ThermalConductivity

|

Medium

|

Medium to High

|

Low

|

Medium

|

|

Thermal Shock

|

Low

|

Medium to High

|

High

|

low to Medium

|

|

Electrical Resistance

|

High

|

low

|

High

|

/

|

|

Chemical Resistance

|

High

|

low to Medium

|

Medium

|

/

|

|

Oxidation Resistance

|

Medium to High

|

low

|

low

|

/

|

|

Machinability

|

Medium

|

low

|

Medium

|

/ |

|

Produ

Related Search

Gauge Block

Precision Ceramic

High Precision Bearing

High Precision Part

High Precision Sensor

Building Block Sets

More>>

Find more related products in following catalogs on Hisupplier.com

Company InfoDongguan Ming Rui Ceramic Technology Co.,ltd [China (Mainland)]

Business Type:Manufacturer You May Like:

Printable Page

Bookmark this page

Sitemap XML About HiSupplier Help Center Customer Service Friend Links Site Map Archives Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español Copyright © HiSupplier.com Online Inc. All Rights Reserved.

|